Equipment Explorer: Creating a New Market Category

By AJ

Today's equipment dealers face the daunting task of positioning farm equipment to prospective customers amid a market environment that includes heavy competition, supply chain challenges, and volatile environmental conditions. Add to this that the average cost of farming machinery is north of $250,000 per machine/implement while some equipment can cost over $1 million dollars for a single machine.

What tools do these dealers deploy to help show the operational, agronomic and economic benefits of their products? Benchmarked data, brochures, spec sheets, online calculators and or spreadsheets? Is a brochure or spec sheet actually a tool?

Ultimately, these "tools" are simply a means of presenting data to a prospective customer that may compel them. The list of "what" may compel the prospective customer can be long and very intimate. The best of the best understand their customers' problems and present products as solutions.

So what are the problems with current tools?

Benchmarked Data: Often Feels Cherry Picked

Such data is typically deployed via website content, social media posts, product brochures and various ads. The new DEF456 has 15% higher throughput than the ABC123.

Online Calculators and Spreadsheets: Not Accurate

Many OEMs and agriculture equipment dealers utilize online calculators and or spreadsheets designed to capture the farmers equipment and financial information to present comparative data to a prospective customer.

Let's breakdown how online calculators and spreadsheets work:

Enter in the farm size in acres or hectares, enter in the operating speed of equipment and the operating width of equipment.

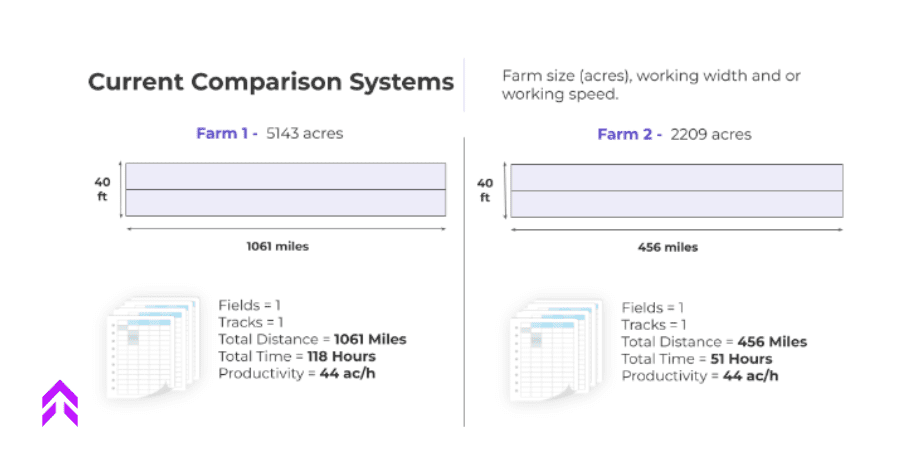

What you get is a straight line calculation. Equipment DEF456 is 40 ft wide, operates at 9 MPH across XXXX acres. Here underlines the problem: no matter what size of farm, number of fields, field shape, obstacles etc. the current comparison system will result in identical productivity for every farm in the world when the same speed and width is entered. This holds true for other parameters as well including GPS accuracy, section control and cost savings calculators.

We have never seen two identical fields let alone 2 identical farms. So do current comparison systems help farmers make the most well informed purchase decision possible, or do they state the obvious:

"It's common sense that increasing operating speed x 1 MPH or increasing operating width x 10 ft will improve productivity".

What makes Equipment Explorer so unique is that it is powered by Verge Ag's industry leading path planning software. Equipment Explorer actually path plans each and every field across a selected farm for current and prospective equipment.

What is a path plan? The creation of an optimal path that guides farm equipment to completely cover a field while avoiding all known obstacles. The software calculates an efficient coverage route for each unique field which includes headlands passes, interior tracks and turns.

Equipment Explorer results include:

- Total number of tracks

- Total distance

- Total time

- Coverage and pass to pass overlap

- Section Control

- Productivity

- Savings

Hit Your Optimal Seeding Window with High Speed Planter Productivity Simulations

Considering purchasing a new high speed planter or retrofitting your current planter? There are many reasons a farmer may choose to replace or retrofit a planter. Amongst them is completing planting in less days, therefore increasing the probability of finishing planting within the optimal window.

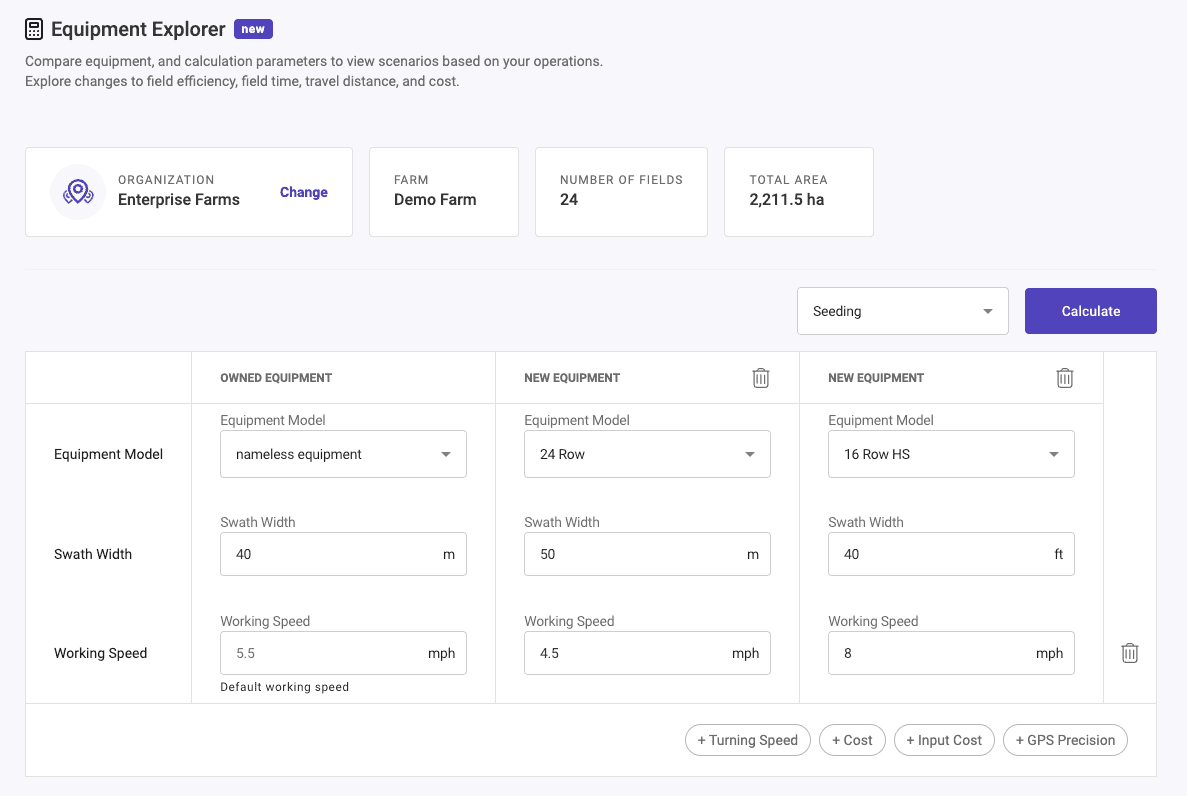

Equipment Explorer provides an interactive and informative experience between dealership and customer. It's as simple as 1, 2, 3.

- Select fields that make up the farming operation

- Enter in the header width and operating speeds for the current on farm Planter plus up to 2 prospective new Planters.

- Run scenario

Equipment Explorer utilizes our proprietary path planning algorithms to create an efficient path plan for each machine selected across all fields. Every headland pass, inner track and turn required to completely cover each and every field.

The result is accurately simulated planting hours for each planter. So, do you want to know how much actual time (hours/days) that new or retrofitted planter can save you?

Help your customers make the most well informed purchase decision possible.

Ready to Transform Your Equipment Sales?

See how Equipment Explorer can help your dealership

Contact Us