Scaling CTF Planning to 133 Paddocks in Australia

By Kate Witham, Farmanco

GRDC Grain Automate Project · December 2025

Key Messages

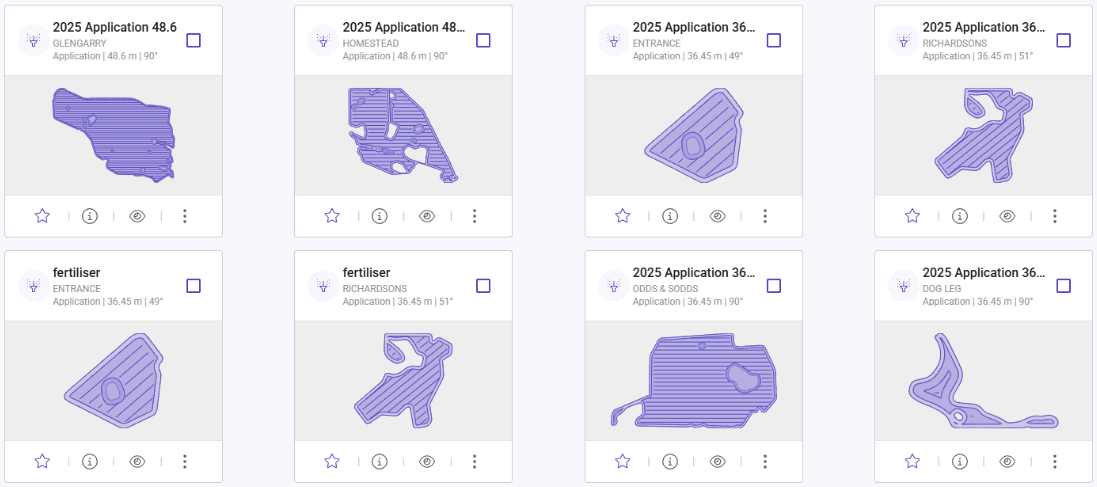

- Optimised paddock planning for new paddocks: Verge Ag's Launch Pad generated GPS guidance runlines and redesigned layouts for Controlled Traffic Farming (CTF), including incorporation of 15-degree deep-ripping offsets.

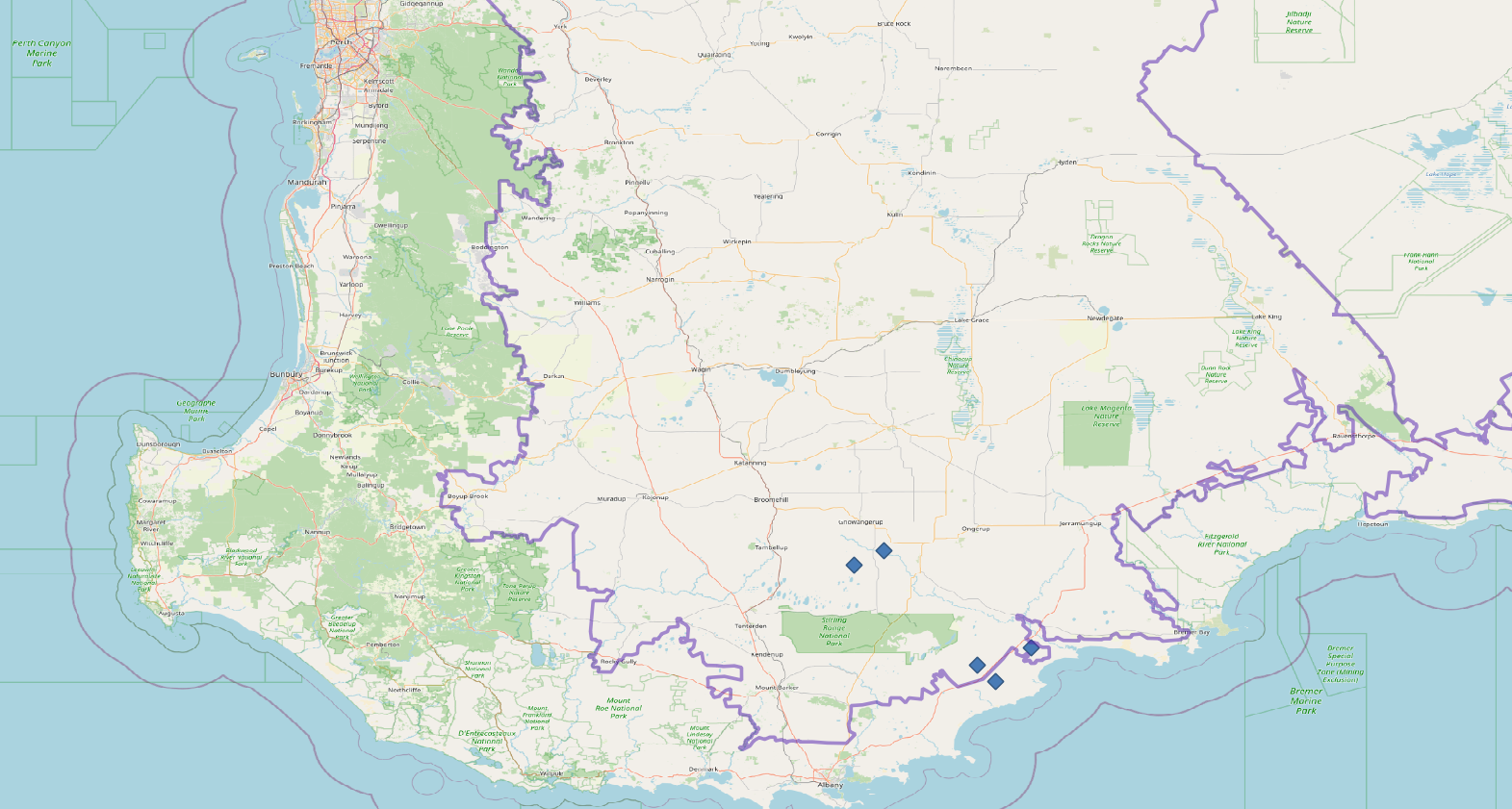

- Consistency across farms: Across 133 paddocks spanning five locations in Western Australia's Great Southern, Launch Pad standardised CTF lines using edge alignment and optimised headings. The platform accommodated diverse paddock layouts, two guidance systems, and four machinery widths.

- Vision for autonomy: Launch Pad delivers many efficiencies associated with autonomous equipment, including full-route planning and standardised execution, using existing autosteer and guidance systems. This reduces reliance on expensive OEM autonomy unlocks or capital investment in new autonomous machinery.

Background

Launch Pad, developed by Verge Ag, is a web-based precision agriculture platform that enables growers to create optimised machinery path plans. Its objective is to reduce fuel use, working time and environmental impact while improving operational consistency. The software generates GPS-compatible routes based on paddock boundaries, machinery specifications and operational goals. It plans the most effective way for equipment to move across a paddock, reducing in-cab decision-making and improving overall productivity. When combined with autosteer and high-accuracy guidance systems, Launch Pad enables supervised autonomy, where operators focus on monitoring rather than steering.

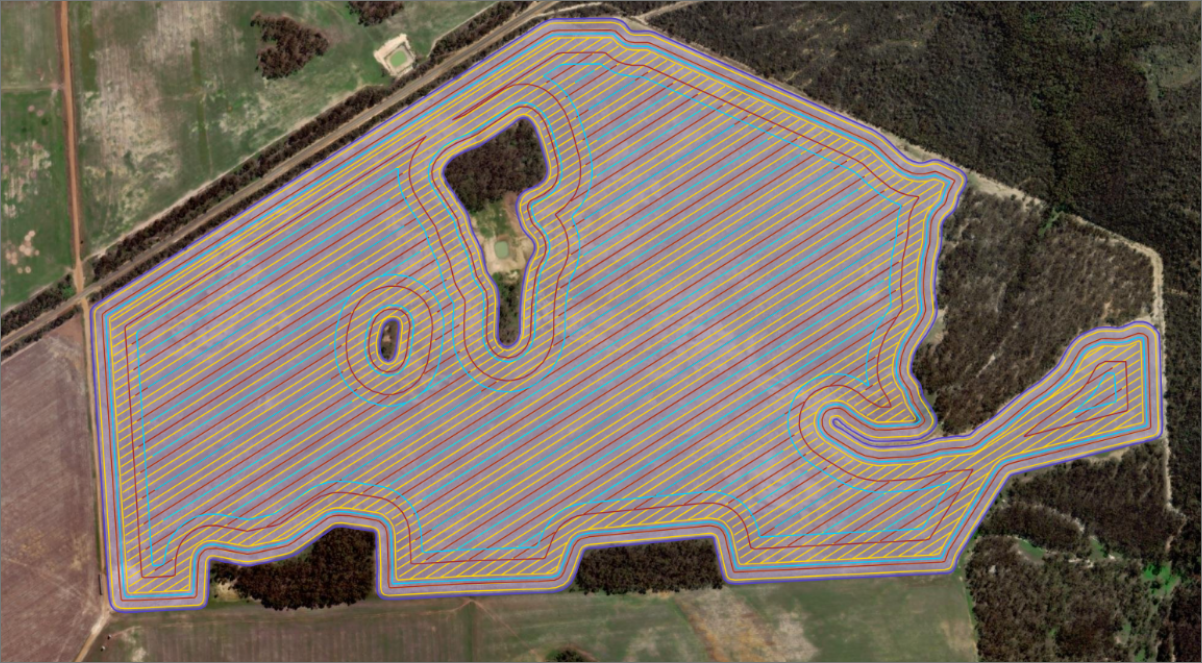

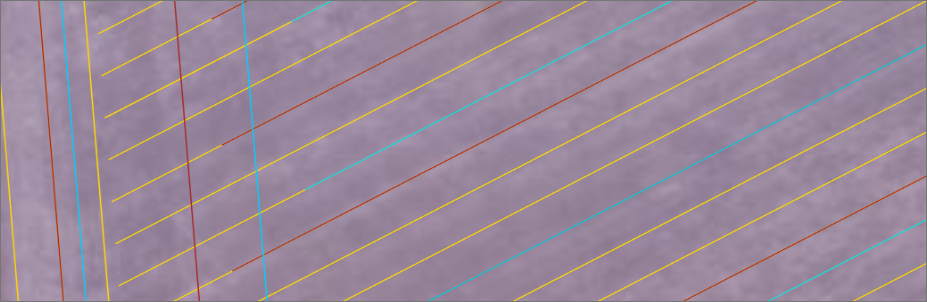

Another application for Verge Launch Pad is creating and utilising common runlines for Controlled Traffic Farming (CTF). CTF is a system that incorporates permanent wheel tracks used by machinery across all operations (where possible) throughout the season. In CTF systems, a master runline is established as the starting point in the paddock, and all subsequent operations are based on this line. By matching the operating width and track spacing of all cropping machinery, compaction is confined to designated wheel tracks (also referred to as tramlines) within the paddock.

When establishing new runlines for CTF, there are many factors to consider to ensure future operations are time-efficient, with reduced overlap or missed areas, the least number of tracks and turns, and minimal adverse effects on soil health such as erosion risk and compaction. Small inefficiencies in design can accumulate over time, resulting in significant losses in time and profitability. This is why planning and comparing options for each unique paddock can be not only difficult but also time-consuming, especially without assistance from programs such as Launch Pad, which simplifies this process by generating and managing common runlines and optimising layouts for efficiency and sustainability.

Case Study Snapshot

- Person

- Ben Slater, Strathaven Farm manager

- Farm

- Nymann Strathaven

- Location

- Great Southern Region, Western Australia

- Area

- 12,000+ ha (Cropping: 9,800+ ha)

- Crops

- Canola, wheat, barley, lupins

- Equipment

- Fendt tractors, Agrifac sprayers, JTA trailing sprayers, Sonic Boomsprays, CLAAS harvesters

- Machinery Guidance

- Fendt and Trimble

- Machinery Widths

- 12, 24, 36, and 48 m

The Challenge

For Ben, the farm manager at Strathaven managing multiple people and planning operations across variable environments, the overarching priority is to increase efficiency and standardise paths across both established and newly acquired paddocks.

After doubling the farm's land base, several challenges were identified with the integration of new paddocks:

- Newly obtained paddocks required common runlines for CTF to be created

- New paddocks were smaller and often had more complex layouts/shapes compared to the existing paddocks closer to Gnowangerup

- Designing efficient run lines required factoring in multiple machinery types, machinery widths, and distributing to two guidance systems (Fendt and Trimble) for use across varied operations and staff backgrounds

- Deep ripping planning across existing and new paddocks requires a 15-degree offset from run lines, which also makes the master CTF runlines difficult to see post-ripping

For Strathaven Farms, CTF planning using Launch Pad was particularly important in 2025. The software simplified the integration of the new paddocks with no preexisting runlines into their existing CTF system and machinery configurations, mitigating potential inefficiencies such as wasted fuel, lost time, and inconsistent operations. These issues could accumulate across future seasons. With multiple staff members (some being in their first year of using machinery) it was particularly important to provide clear and efficient route planning.

For the new paddocks, Launch Pad's intelligent route planning created optimised run lines for each paddock based on:

- The least number of tracks required

- The highest number of track overlap between operations

- The least distance travelled across the various equipment types and activities

Deep ripping further complicated operations, as the 15-degree offset from run lines historically made it difficult to visually track previous paths. Launch Pad simplified this process by incorporating the required angle change into the plan, while still ensuring operators could maintain efficiency in the adjusted path.

Processes and Features of Launch Pad

Ben found the process of generating new plans in Launch Pad to be fairly straightforward, with no notable difficulties encountered when transferring them from his laptop to the guidance systems across the different machines.

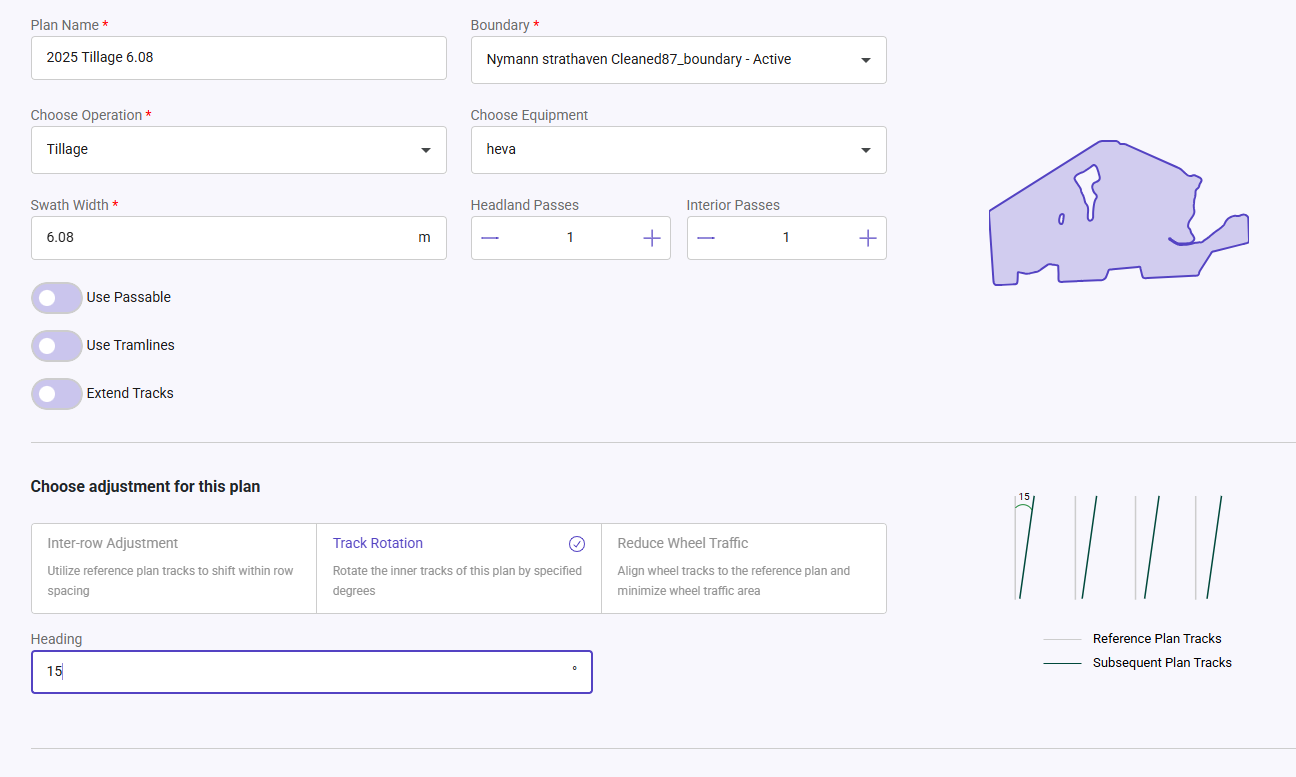

Plan From Feature

The "Plan From" feature in Launch Pad was useful for Ben where he was comparing different machinery types and widths across both existing and new paddocks. By starting from one operational plan (e.g. seeding), he could use the existing headings and start points to design a secondary activity plan, such as a spray application. This feature allowed Ben to create a seasonal plan (a plan for each operation during the season) which aimed to maximise the number of shared tracks across four machinery widths to minimize the area trafficked, while still providing measurable insights for each route option such as working time or number of turns.

This "Plan From" feature was also useful when planning changes in run line angles, such as deep ripping on 15 degrees.

Edge Alignment of New Runlines

When designing paddock plans for the new paddocks with no existing runlines, Ben often selected the "edge alignment" option in order to follow the longest straight edge for most paddocks. This was done to create cohesion across paddock plans, and again reduce inefficiencies and share as many of the same CTF lines across operations. Edge alignment was the right approach for the system, proving to consistently deliver the highest efficiency metrics, and aided in standardising routes. This approach was done on a paddock-by-paddock basis for each new field.

Some paddocks had a "longest edge" identified by the program, though headland vegetation meant straight lines were not possible. In these instances, Launch Pad was able to identify a more efficient route, which often followed the next longest uninterrupted straight edge of the paddock, or the route that involved the least number of tracks/turns.

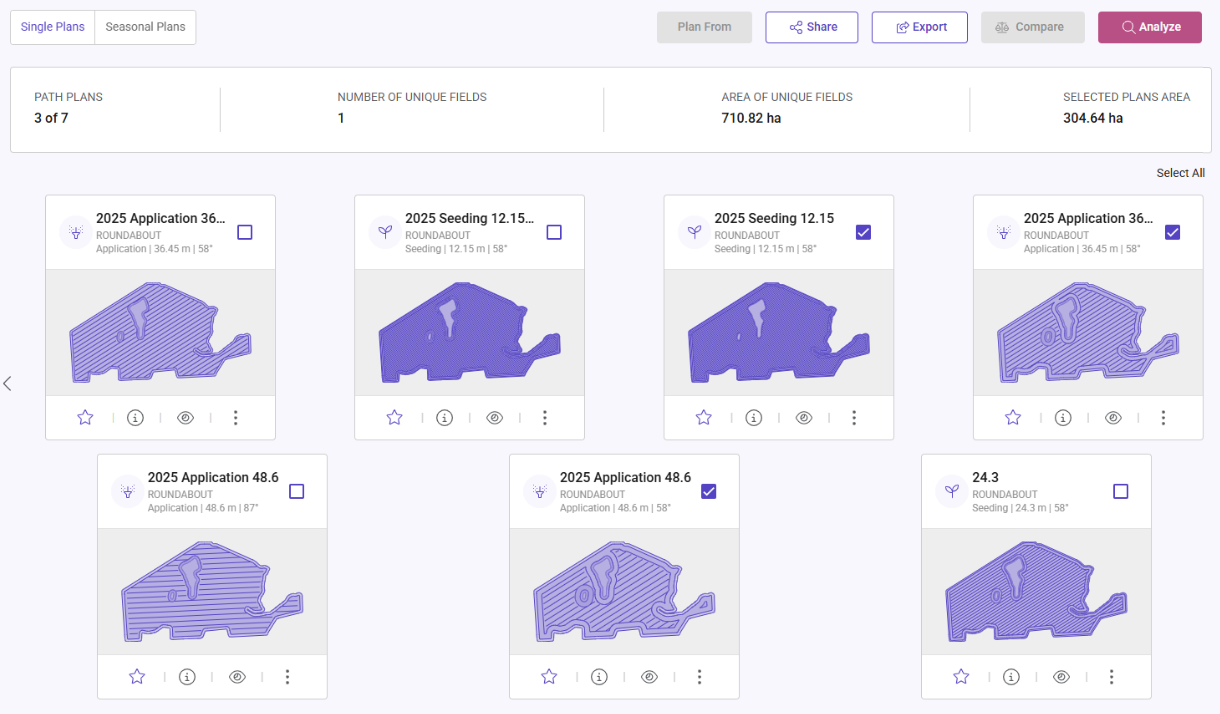

Analysing Seasonal Plans

Ben found the "Analyze Path Plans" Launch Pad feature to be also useful in comparing efficiency metrics across various machinery widths. Ben was able to compare metrics within each paddock plan, as well as being able to visually see the overlaid routes across the seasonal plan and number of shared CTF tracks. This allowed the most efficient combinations and AB line headings to be planned pre-season for all paddocks.

Ben used a similar approach when identifying the most compatible and efficient AB lines in paddocks where no preexisting CTF lines were available.

In some instances, Launch Pad identified the shortest or the fastest routes, which involved complex turns that were not compatible across all machinery widths. By comparing different machinery, headings and routes in the overlaid plan, the most consistent yet efficient route was able to be identified and fine-tuned.

Results

Some of the improvements from path planning in efficiency, consistency, and machine operation included:

- Less time spent planning new paddock paths

- Ease of integration for new CTF lines

- Increased efficiency in machinery distance and time taken across activities

- Improved consistency and cohesion across paddock paths, despite a range of equipment, staff, paddock types, guidance systems and operations

- Rapid on-the-go changes to paddock plans increased efficiency and problem-solving abilities

- Machinery optimisation

- Optimised AB lines

- Route standardisation using edge alignment methodology

- Reduced overlap

When looking at the same "Roundabout" case study paddock, new run lines were determined by evaluating the most efficient pathways and headings for operations that typically demand the greatest time investment, namely seeding and harvesting. By prioritising these time-consuming operations, the most efficient and cohesive routes were selected.

In this scenario, Launch Pad identified a heading of 57.9 degrees to be the most efficient option at seeding and harvest. This heading had the least number of tracks and time required to complete operations.

Standard 90-Degree Heading

| Metric | Horsch Seeder 12.15 m |

Sonic Sprayer 36.45 m |

CLAAS Harvester 12.15 m |

|---|---|---|---|

| Avg. passes in season | 1 | 4 | 1 |

| Number of tracks | 145 | 50 | 148 |

| Total tracks in season | 145 | 200 | 148 |

| Total tracks over season | 493 | ||

| Time to complete (mins) | 635 | 115 | 790 |

| Total time over season (mins) | 635 | 452 | 790 |

| Total Time (hours) | 31.3 | ||

| Overlap (ha) | 2.53 | 6.80 | 2.54 |

| Total overlap in season (ha) | 2.53 | 27.20 | 2.54 |

| Total Accumulated Overlap (ha) | 32.27 | ||

| Total Average Overlap % | 5.32% | ||

Table 1. Key metrics for Roundabout Paddock in 2025 using a conventional 90-degree heading. Data extracted from Verge Launch Pad.

Optimised 57.9-Degree Heading

| Metric | Horsch Seeder 12.15 m |

Sonic Sprayer 36.45 m |

CLAAS Harvester 12.15 m |

|---|---|---|---|

| Avg. passes in season | 1 | 4 | 1 |

| Number of tracks | 139 | 49 | 144 |

| Total tracks in season | 139 | 196 | 144 |

| Total tracks over season | 479 | ||

| Time to complete (mins) | 627 | 108 | 767 |

| Total time over season (mins) | 627 | 432 | 767 |

| Total Time (hours) | 30.4 | ||

| Overlap (ha) | 2.20 | 5.82 | 2.09 |

| Total overlap in season (ha) | 2.20 | 23.28 | 2.09 |

| Total Overlap (ha) | 27.57 | ||

| Total Average Overlap % | 4.55% | ||

Table 2. Comparison of key operational metrics for Roundabout Paddock using the optimised 57.9-degree heading (least time to complete seeding).

14

Fewer tracks per season

0.9 hrs

Time saved per season

4.7 ha

Less overlap per season

And that's just one paddock. Strathaven Farms has 133.

Quantifying Overlap Costs

Some benefits, such as greater planning ease, improved operational compatibility, and enhanced confidence in operations, can be considered intangible. However, certain efficiency gains can be quantified such as overlap costs.

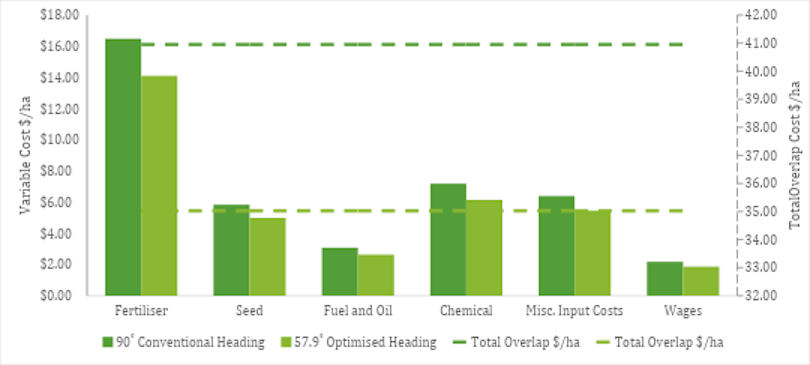

In evaluating the monetary impact of reduced overlap in the optimised/fastest paddock plans versus a plan using a conventional AB heading, average benchmark data from Albany Port Zone growers over the past five years was applied to key cost parameters including fuel and oil, fertiliser, chemicals, and wages.

| Cost Category | Benchmark $/ha |

90-Degree Heading | 57.9-Degree Heading | ||

|---|---|---|---|---|---|

| Cost/paddock | Cost/ha | Cost/paddock | Cost/ha | ||

| Fertiliser | $310 | $1,666 | $16.49 | $1,425 | $14.11 |

| Seed Costs | $110 | $591 | $5.85 | $506 | $5.01 |

| Fuel and Oil | $58 | $312 | $3.09 | $267 | $2.64 |

| Chemical | $135 | $725 | $7.18 | $620 | $6.14 |

| Misc. Input Costs | $120 | $645 | $6.38 | $551 | $5.46 |

| Wages | $41 | $220 | $2.18 | $188 | $1.87 |

| Total seasonal overlap cost | $4,158 | $3,556 | |||

| Overlap cost per hectare | $40.95 | $35.03 | |||

Table 3. Benchmark cost data derived from the Albany Port Zone (5-year average) applied to "Roundabout" paddock comparing conventional and optimised heading options.

In this scenario, Strathaven Farms reduced seasonal overlap costs by approximately $6 per hectare (equating to nearly $600 over the one paddock) when comparing conventional and optimised CTF lines in one of the new paddocks. When carried forward over multiple seasons, these savings demonstrate how incremental efficiency gains can compound into substantial improvements in overall operational profitability.

Challenges

Some limitations encountered included:

- Absence of pre-saved heading templates required manual entry across paddocks

- Each downloaded plan required manual extraction prior to USB transfer

- Certain components of the route planning engine required refinement, particularly in turn planning logic

These issues did not prevent implementation but represent opportunities for product refinement.

Next Steps

Strathaven Farms will continue leveraging Launch Pad as they work toward autonomy and the standardisation of paddock plans and identifying the most compatible paddock routes.

With CTF lines now established across all paddocks, Ben's focus for next season is to apply newly updated Launch Pad features to operations, and continue to use Launch Pad to refine the existing plans, "tidying up" where needed.

Acknowledgements

Through the Grain Automate initiative, Grains Research and Development Corporation (GRDC) has partnered with Verge Ag and the Australian Controlled Traffic Farming Association to support the acceleration and adoption of machine automation, autonomy and digital technologies in the Australian grains industry. The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC.

We extend our thanks to Strathaven Farms, Ben Slater, and owner Knud Nymann for generously sharing their time and insights that made this case study possible.

Project Code: VER2304-001RTX

Ready to Optimise Your Operations?

Discover how Launch Pad can transform your paddock planning

Get Started Now