Success Case: Sprayer Track Shut-Off

By Antonela

This field execution day focused on testing the efficiency of automatic planter shut-off based on sprayer tracks, with the primary goal of preventing over-seeding and compaction while ensuring precise and efficient planting.

The planting and spraying projects were planned using Launch Pad and executed in the field in collaboration with the technical team from PlantiMais, enabling precise integration between operations and execution aligned with best practices in precision agriculture.

A fundamental highlight of this demonstration was the implementation of the "zero compaction" concept, which brings significant advantages for crop establishment, such as:

- Better utilization of fertile zones without soil compaction caused by machinery

- Prevention of emergence failures due to prior trampling

- Reduction in seed and input usage

- Greater uniformity in planting and better predictability in crop development

This document presents the test conditions, technical configurations, and observed field results.

Test Details

The test was conducted in Mato Grosso do Sul, Brazil, focusing on a corn crop, with planting carried out on March 17, 2025.

The planting operation was executed using a Valtra Momentum planter, configured with 26 rows spaced at 50 cm, covering a total working width of 13 meters. The tractor was equipped with a CNH Pro 700 monitor and the planter was equipped with a Precision Planting 20/20 monitor, ensuring high-precision seed placement and real-time data collection during the operation.

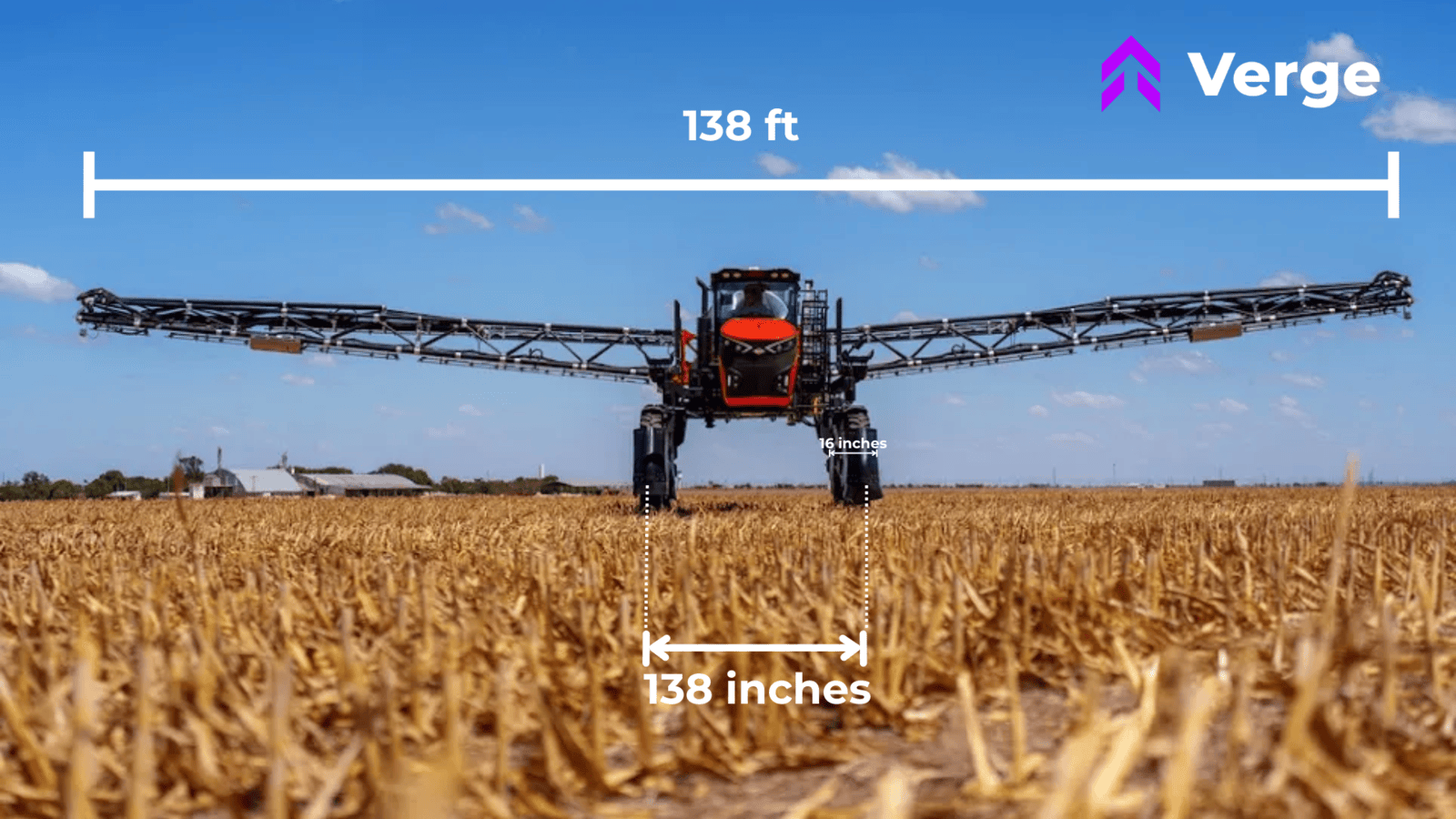

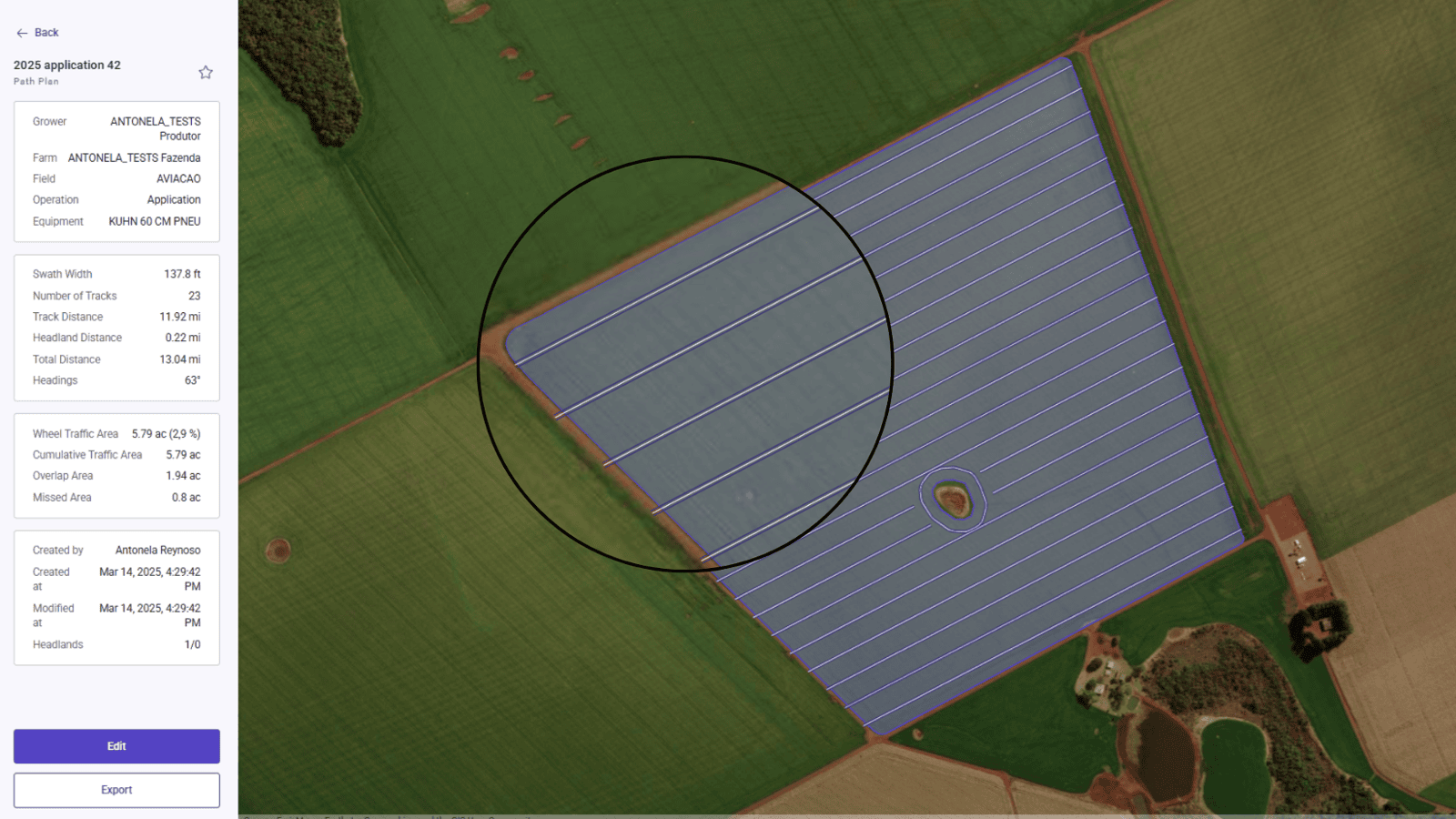

For the spraying operation, a Kuhn Stronger 4000 sprayer was used, guided by a Trimble GFX 750 (AgData) monitor. The sprayer had a working width of 42 meters, with tire widths of 40 cm. However, for purposes of precise seed shut-off in overlap areas, a tire width of 60 cm was configured to ensure proper on/off control. The distance between tires was 3.5 meters, which was crucial for aligning the planting strategy with the tracks left by the sprayer.

Planting was performed with Brevant 2701 seeds. The seeding rate applied during the operation was 60,000 plants/ha, in line with the recommended density for ideal crop establishment. The seed was priced at $213.36 per bag (with 60,000 seeds per bag), representing a strategic investment in high-quality genetics aimed at maximizing yield potential and field efficiency.

Project Planning in Launch Pad

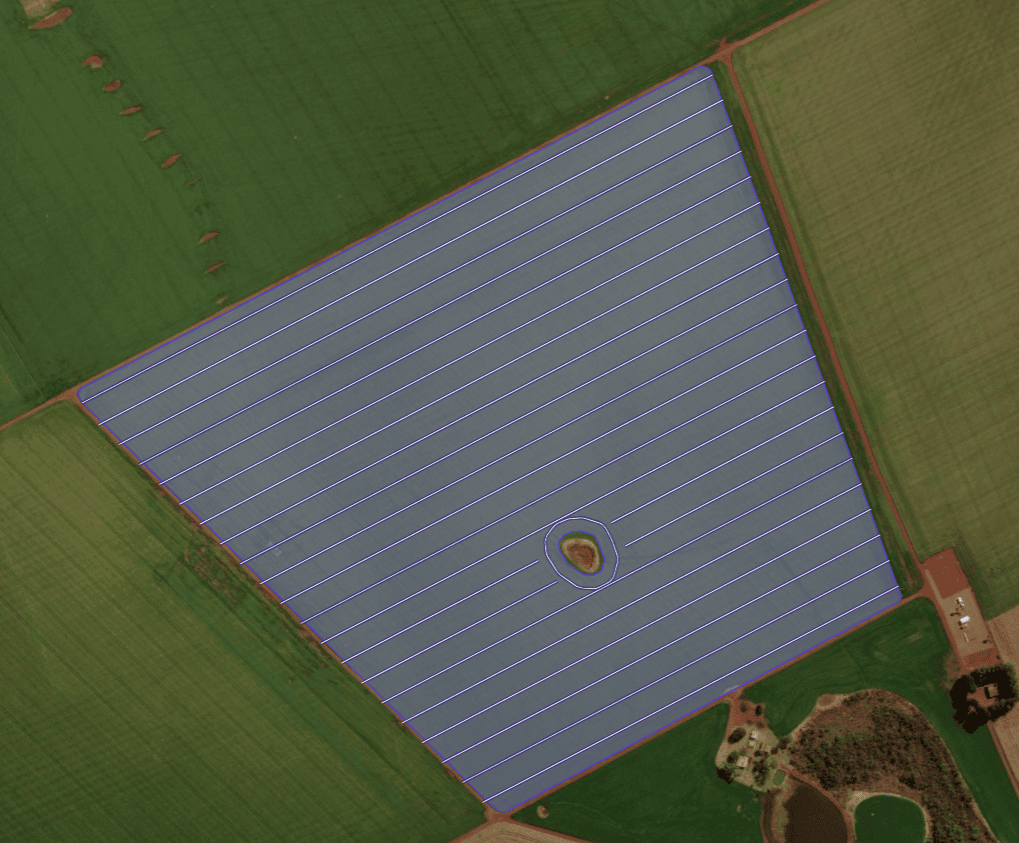

Both the spraying and planting projects were created using Launch Pad, a digital platform designed to simplify and optimize field operations through precise planning and equipment integration. For this test, the spraying map was created first, defining the working width (42 meters), including the dimensions of tire tracks to guide the planting cut-off logic.

Based on this initial plan, the planting project was generated by rotating the rows by 4º, incorporating the sprayer track to allow precise row-by-row shut-off.

This synchronization allowed the planter to automatically stop seed flow over the sprayer track, effectively demonstrating the zero compaction strategy and reducing seed waste. The perfect alignment between the two operations ensured high precision and better agronomic results.

Results

The projects were executed successfully, with all equipment responding precisely to the parameters defined in Launch Pad. The seeding operation correctly followed the sprayer tracks, and the automatic shut-off system functioned as expected, avoiding overlap and ensuring a clean and uniform planting pattern.

The producer expressed a high level of satisfaction with the result, particularly highlighting the efficiency gains, reduction in seed waste, and visible planting quality throughout the field. The integration between planning and execution stages proved to be reliable and replicable, reinforcing the benefits of zero compaction practices.

By utilizing the automatic seed shut-off system integrated through Launch Pad, significant savings in seed usage were achieved. With the system preventing over-seeding in areas already covered by the sprayer, we effectively reduced seed waste.

Key Results

- Unplanted area (sprayer track): 2.28 ha

- Reduction in seed consumption: 2.9%

- Seeds saved: 136,800 seeds per hectare

- Total savings: $486

These savings contribute not only to reducing operational costs but also to a more sustainable approach to crop management, maximizing the efficiency of each input.

To further illustrate the results, photos and videos were captured during the operation, showing the machinery in action, field conditions, and the system's technical performance.

Conclusion

The success case presented by Verge Ag clearly demonstrates how the integration of digital planning and automatic shut-off technology can transform operational efficiency in the field. By precisely aligning spraying and planting operations through the Launch Pad platform, it was possible to eliminate overlaps, avoid soil compaction, and reduce seed waste. This approach not only optimizes input usage but also promotes more uniform crop establishment, leading to significant agronomic gains.

In this case, the use of a large sprayer in a relatively small area resulted in fewer tire tracks. However, in a situation with a higher seed population and a smaller sprayer, the track area would be larger, and the potential for even greater savings would be significantly amplified.

This scenario highlights the impressive potential of technology to optimize input usage. The experience reinforces the value of precision agriculture solutions in the pursuit of more sustainable and profitable farming.